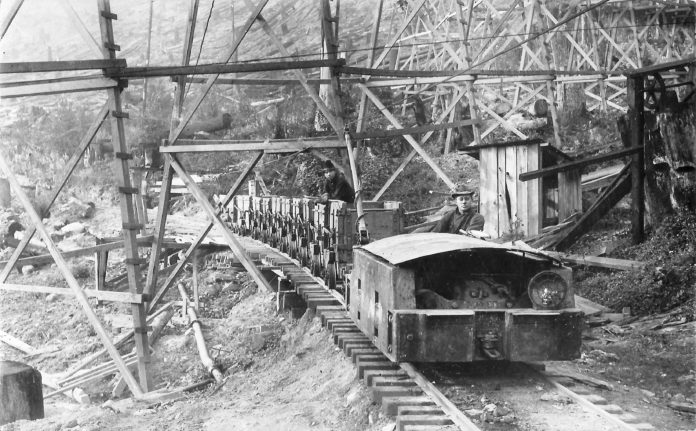

This column is the fourth in a series about Taylor, a coal and clay mining community located east of Hobart in an area now part of the Seattle City Watershed. Seen here is an electric motor pulling a short train of wooden coal cars. To the left of the trolley driver is a wooden post connected to a copper wire charged with high voltage direct current electricity which powered the motor. Coal was used to fire the clay and shale through a vitrification process which baked molded products into pipes and liners. Taylor’s clay was particularly suited for clay tile used in sewer lines.

While Taylor’s coal mines were a typical room and pillar operation, their clay was mined by several methods during different periods. Some clay was mined with the coal as the sedimentary formation contained seams of both. Other times the clay beds were mined from open-cut quarries at the outcrop of thicker strata. But the principal system was called the “glory-hole” method. After a loading-tunnel was dug horizontally into the beds, blasting created a funnel-shaped opening with clay and shale dropping to the loading tunnel then hauled to the plant. There the raw material was stockpiled for further processing through de-airing units, pug mills, auger machines, and a dry press when needed. Sewer pipe was Taylor’s primary product and varied in size from 3 to 30 inches. This photo comes courtesy of the Maple Valley Historical Society. Next week’s column will be the final in this series about Taylor – the ‘lost’ town of the Cascade foothills.